Packaging food stuffs is practical and important. Packaging protects food stuffs from germs, may help keep them fresh for longer periods of time, and allows preparation of defined amounts for the consumer.

Can packaging become a problem?

Quite apart from the ecological issues caused by ‘too much’ packaging or packaging made of plastics, it is possible that various compounds could be transferred to the food itself from the wrapping, paper and cardboard cartons or plastic containers. The amount of the compound that migrates into the food stuff is dependent on how soluble it is within the food matrix. For example, a lipophilic wax will transfer into an apple juice in very small amounts only, while the same wax will migrate in much larger quantities into olive oil.

Whether or not this transfer is relevant, or perhaps even problematic in regards to toxicology, can be determined via migration tests. In compliance with EU Norm requirements, the food stuff/packaging combination is simulated by way of modelling. For the combination cheese/plastic wrap, the model would work as follows: an oil would be brought into contact with the wrap and the quantity of substances that migrate from the wrap to the oil within a specific time frame and under defined environmental conditions would be determined. This is also known as total migration. Afterwards, it is possible to analyse the type and amount of each individual substance that underwent migration. This is known as specific migration.

What type of substances transfer to food stuffs?

Over the last few years, reports have appeared in the media regarding

- Plasticiser in olive oil (from the hoses that connect system parts in the mill)

- Photostabilisers in yoghurt (from the print on yoghurt containers)

- Petroleum-derived hydrocarbons in all sorts of food stuffs (from cardboard boxes)

- Nonylphenol in lid seals

- Pentachlorphenol in tea (from wooden boxes)

- Acetaldehyde in mineral water (from PET bottles)

- ESBO (Epoxydized Soy Bean Oil) from lid seals

- and more

How do we reduce the risk of food contamination?

The food producer and packager should not rely on the promise that packaging is ‘suitable for food’; instead, they should know which materials they are using and what substances they contain. This is really the only way to decide on suitable packaging for the product. The relevant information should be provided by the packaging supplier. However, it is often the case that even the packaging supplier and producer do not exactly know which substances are contained within the raw materials. This is particularly true for areas in which recycling materials are in use. But it is also advisable to carry out quality control for other raw materials and packaging, for example those purchased from China.

For packaging of all types, particularly in light of the high rates of recycled materials: less is more

| Phthalates (SVHC) in materialMCSV1 |

| ESBO in materialMCWM1 |

| Epoxy derivatives according to V (EG) 1895/2005 incl. BPA, BADGE and Cyclo-di-Badge in migrate/material/foodKNT02 |

| global migration 10% EthanolZKE01 |

Bildnachweise

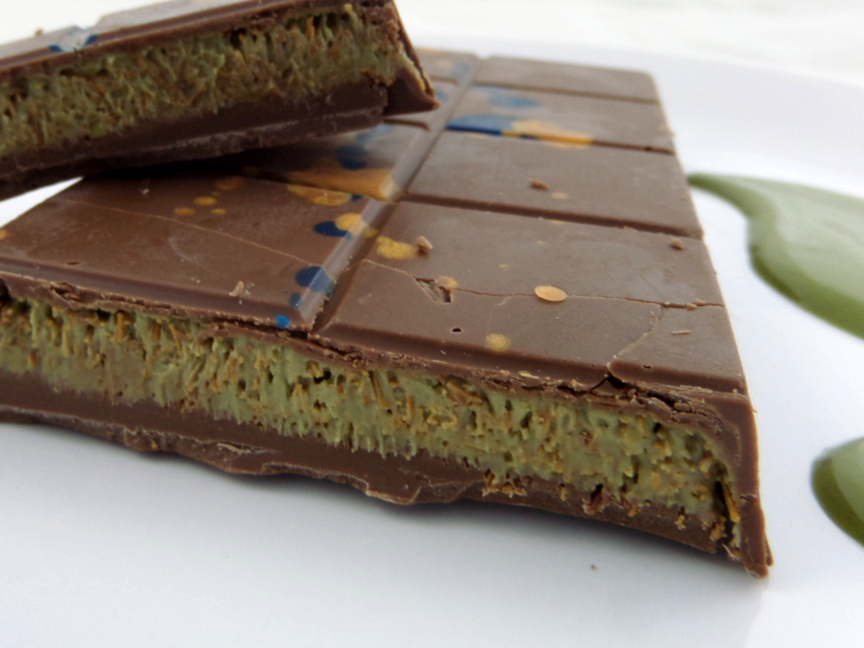

- Titelbild + Beitragsbild | Quelle: my-lab International | Modifiziert von my-lab International